Hydroforming is a metal fabrication and forming method that allows the shaping of various metals like stainless steel, copper brass, and aluminum. This is a low-cost and unique type of molding that uses highly pressurized fluid to shape metal.

In general, two categories are used to describe hydroforming: sheet hydroforming and tube. Sheet hydroforming employs a single die, and the sheet is made of metal which is pushed into the die using high-pressure water that is poured onto either side, forming what is desired.

Tube hydroforming refers to the expansion of tubes made of steel into shapes with two die halves that contain the tube in its raw. Hydroforming replaces the traditional method of stamping two halves and then welding them. You can know more about hydroforming presses online.

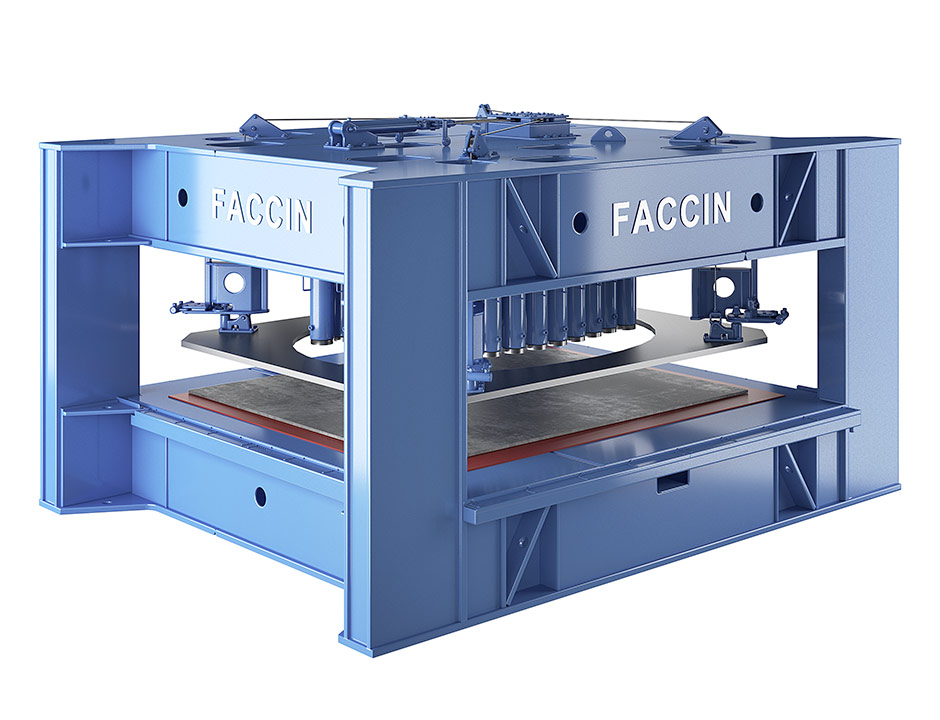

Image Source: Google

It can also be used to make parts faster through removing welding as in creating intricate forms and contours. Parts made with this method offer a range of advantages in manufacturing, including seamless bonding, greater parts' strength, and the ability to keep excellent surfaces for finishing purposes.

In comparison to traditional metal-stamping and welded parts Hydroformed parts are lighter and have a lower price in terms of unit cost, as well as come with a greater stiffness to weight ratio.

These processes can be employed for the production in a single-stage of components, which saves the use of tools, labor, and other materials.